Comparing Traditional Approaches to Experimental Design

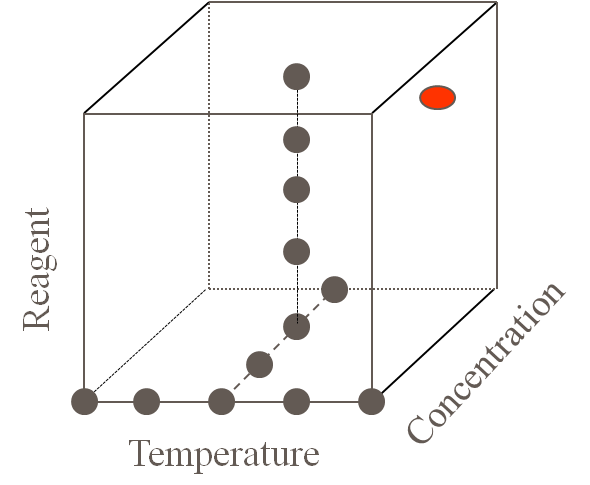

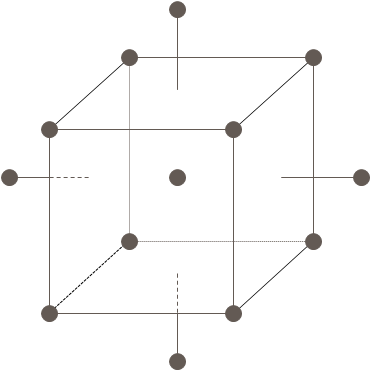

The traditional approach taken to develop a new process is One Factor at a Time (OFAT) (Figure 1). Experimental design, on the other hand, is a structured set of tests of a process to investigate potentially significant factors that helps to establish cause and effect relationship on the output (Figure 2) The advantages and disadvantages of both approaches are discussed in Table 1 and Table 2 below.

| Advantages | Disadvantages |

|---|---|

|

Widely taught |

Limited coverage of the experimental space |

|

Straightforward |

May miss the optimal solution |

|

|

Fails to identify interactions |

|

|

Inefficient use of resources |

| Advantages | Disadvantages |

|---|---|

|

Systematic: Thorough coverage of experimental “space” |

Minimum entry of ca. 10 experiments |

|

Efficient: Able to establish solution with minimal resource |

You may have to run experiments that you anticipate will “fail” |

- Route Selection

- GMP

- Introduction to Process Engineering

- Route Selection and Scale Up: Case Study and Exercise

- Process Safety

- Reactive Hazards in Scaling Up: Case Study and Exercise

- Design of Experiments

- Some Definitions

- The Experimental Design Process

- Comparing Traditional Approaches to Experimental Design

- Examples of Variables and Responses for a Chemical Process

- Main Effects and Interactions

- Experimental Designs: Factorial Designs

- Experimental Designs: Response Surface Design

- Design of Experiments: Summary and Further Reading

- Reaction Work-up and Product Isolation

- Environmental Legislation

- Abatement and Waste Treatment