The Experimental Design Process

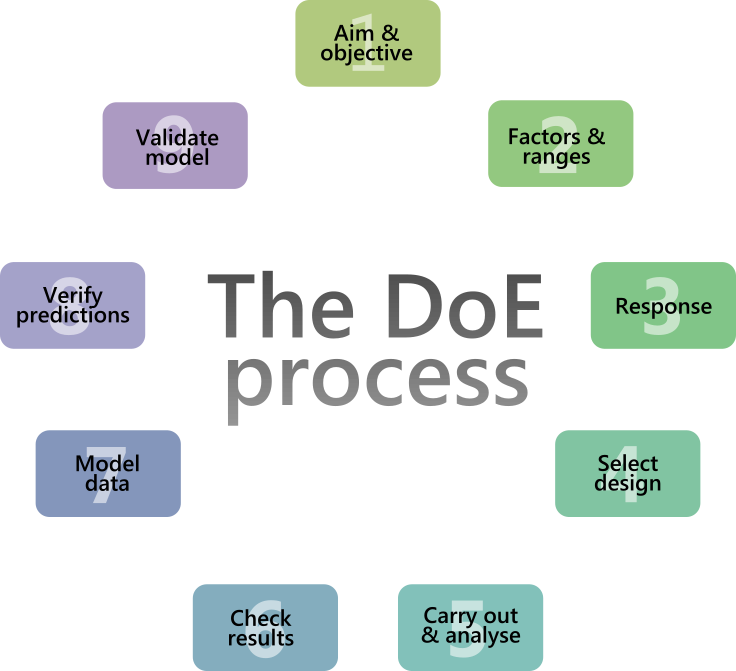

The power of a DoE is directly affected by its construction and execution. Great attention to the design of the DoE is extremely important to increase the chances of extracting useful information. Figure 1 shows the steps to follow when designing and analysing a DoE.

- Define the Objective: the objective will generally be to maximise a response (i.e. yield), to minimise a response (i.e. an impurity) or to hit a target.

- Define the Process and Select Factors to be Studied: define the boundaries of the process to be experimented upon. Investigate or control all known or expected sources of variability for the experiment. The factors are the independent variables that will affect the response and it is important to ensure that it is practical, feasible, and cost effective to select a factor to be studied and to change its level.

- Select a Response and Measurement System: responses are the outputs of an experiment. When analyzing an Experimental Design, you can use as many responses as you are willing to measure. A good measurement system is one that is accurate, repeatable, reproducible, stable, and linear. Taking good samples is a critical aspect of the measurement system. The samples from each experimental run must be representative of the response during that run.

- Select the Experimental Design: the type of design is highly dependent on the number of factors to be studied, the resources available and the level of risk the experimentator is willing to take. Screening experiments are usually the best design choice early in an experimental sequence when many factors are to be explored.

- Execute Experiments Accurately: collect data consistently to minimise variability.

- Check the Results Obtained for any Issues: Repeat experiment if required.

- Model Data: statistical methods are used to establish the relationships between the factors and the response. Interpret the results and consider how they meet the objectives and solve the problem.

- Verify Predicted Results with Confirmation Experiments to Validate the Model.

This is an iterative cycle and you may need to repeat steps 1 to 8 if necessary based on new understanding.

Figure 1: Step by step guide to designing and analysing a DoE

- Route Selection

- GMP

- Introduction to Process Engineering

- Route Selection and Scale Up: Case Study and Exercise

- Process Safety

- Reactive Hazards in Scaling Up: Case Study and Exercise

- Design of Experiments

- Some Definitions

- The Experimental Design Process

- Comparing Traditional Approaches to Experimental Design

- Examples of Variables and Responses for a Chemical Process

- Main Effects and Interactions

- Experimental Designs: Factorial Designs

- Experimental Designs: Response Surface Design

- Design of Experiments: Summary and Further Reading

- Reaction Work-up and Product Isolation

- Environmental Legislation

- Abatement and Waste Treatment